Mastering the Art of Shafting: A Comprehensive Guide to Power Transmission Components

In the world of mechanical engineering, the term 'shafting' might invoke images of intricate designs and rugged industrial components. At first glance, these components may seem like mere metal rods used to transfer power, but in reality, they embody the very backbone of motion transfer in machinery. Imagine a symphony where every note is perfectly aligned to create a harmonious melody; this is the essence of shafting in power transmission. So, what makes these components so essential, and how do they contribute to the efficiency of machines? Let's unravel the mystery of these critical elements and discover their roles in the grand machinery of industry.

Consider for a moment the axle of a vehicle. This unassuming yet crucial component acts as a bridge connecting the drive shaft to the wheels. When we accelerate, we often overlook the intricate dance happening within the axle that enables our vehicles to move smoothly. It's here that we can see the captivating world of shaft design at work. Every aspect of the axle is meticulously engineered to ensure it stands up to the rigors of road travel while efficiently transferring power from the engine shaft to the wheels. If you've ever felt the rumble of power surging through your ride, you know the magic behind a well-designed axle and the art of shafting it brings to the table. Isn't it remarkable how these metallic threads weave a story of motion and energy?

Now, let’s shift gears and delve into the spindle, another fascinating component of shafting. Often used in various industrial applications, spindles serve as the crucial point of rotation for machinery. Think of the spindle as the artist's brush, enabling precision and expression through its movements. Picture this: a lathe spinning a piece of wood or metal, creating a beautiful shape. The spindle’s role influences not just the efficiency of the process but also the quality of the final product. It's no wonder that spindle maintenance is a hot topic among machinists! What stories do spindles tell in your workshop?

On the subject of crafting motion, the propeller shaft exemplifies the marriage of innovation and necessity in shafting. Employed in marine environments, the propeller shaft carries the power generated by the engine straight to the propeller, forcing it to slice through water. This transformative motion propels vessels forward, steering them across vast expanses of ocean. Have you ever gazed overboard, contemplating how such a simple yet complex design thrusts an entire ship through water? Ensuring the integrity of the drive shaft is paramount for safe and effective journeys on the high seas. The harmony of every component, from pinion gears to bearings, allows ship crews to traverse the waves without a hitch.

As we explore the diverse components of shafting, it's crucial to consider the mechanical shaft's broader role in power transmission. Beyond their individual purposes, components like the crankshaft and camshaft symbolize the heart of any engine. These elements convert linear motion into rotational energy, propelling machinery to perform remarkable tasks. Think about the importance of regular shaft maintenance; a well-maintained mechanical shaft can make all the difference in efficiency and longevity. However, the intricacies of these components can often be daunting. So, how do we effectively learn about the shaft assembly and its importance? By unraveling their roles and understanding how they work together, we can appreciate the beauty and functionality embedded in the world of engineering. So next time you hear the word 'shafting,' remember that it’s more than just a technical term; it’s a journey through the complexities of power transmission that keeps our world running smoothly.

From Crankshaft to Camshaft: Navigating the Complex World of Motion Transfer

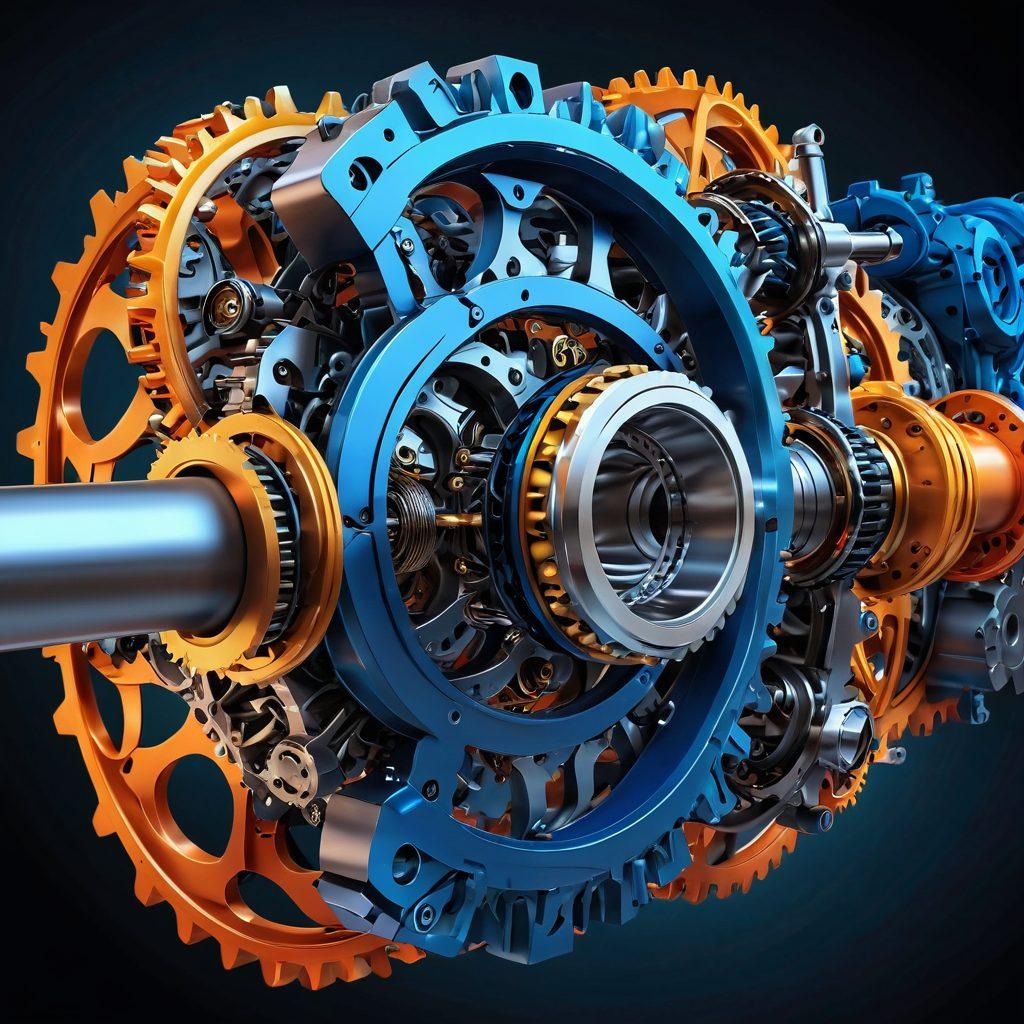

Understanding the intricate dance of power transmission relies heavily on the seamless motion transfer facilitated by various mechanical components. Just imagine for a moment the myriad ways machine parts work together in harmony – where a mere twist of the wrist can ignite the vitality of an engine, thanks to the mechanical magic within a crankshaft or camshaft. The world of shafting is not merely a technical domain; it’s a symphony of engineering, where each player, from the axle to the spindle, carries out a crucial role. So, how do we navigate this complex world of motion transfer in shafts and what can we learn from it?

Let’s dive deeper into the anatomy of power transmission components, where each shafting element reveals its unique character. A drive shaft, for instance, is not only a vehicle's lifeline, but it also exemplifies resilience – transmitting power from the engine shaft to the wheels to keep us moving forward. Have you ever wondered what would happen if a propeller shaft didn’t perform its duty? It’s quite easy to overlook such critical components until they fail. This brings us to an essential truth: understanding shaft design and maintenance is key to ensuring that our machines run smoothly and efficiently. As the saying goes, 'An ounce of prevention is worth a pound of cure.'

Imagine a race car under the hood roaring to life; every rev of the engine relies on a finely tuned rotor communicating with the transmission system. The connection between the pinion and bearing acts like a handshake between old friends—trustworthy, firm, and vital for success. This is no different from encouraging teamwork in the workplace; where every individual must complement each other’s skills and efforts. When we think about the importance of each part in a shaft assembly, it’s a reminder that even the smallest cog can make a significant difference in the bigger machine. Have you ever experienced your own gears slipping in a team setting?

As we explore the diverse configurations of shafts—from the simplistic mechanical shaft to the robust industrial shaft—we become aware of the engineering marvels that hold significant weight in the world of motion transfer. The pivot of the camshaft, for example, plays a crucial role in regulating engine dynamics, much like a conductor maintaining the tempo in an orchestra. This relationship says much about our own lives: the delicate balance of function and motion, of drive and pivot, ensuring every excursion through life resonates with purpose. Do you see a part of yourself reflected in that dynamic?

Yet, understanding shafting is just the beginning. The need for regular shaft maintenance is paramount to extend the life of power transmission systems. Without it, fragile parts like the bearing can lead to a cascade of failures, transforming a minor inconvenience into a monumental setback. So, what's the takeaway? As in life—both in machinery and our everyday interactions—diligent maintenance holds the power to prevent disaster. The art of mastering motion transfer through shafts is not solely about knowledge; it is an actionable commitment to understanding and nurturing the components that make our world go round. Are you ready to actively engage with this engaging discipline and explore the endless possibilities that come with it?

Shaft Assembly Secrets: Maintaining and Designing for Optimal Performance

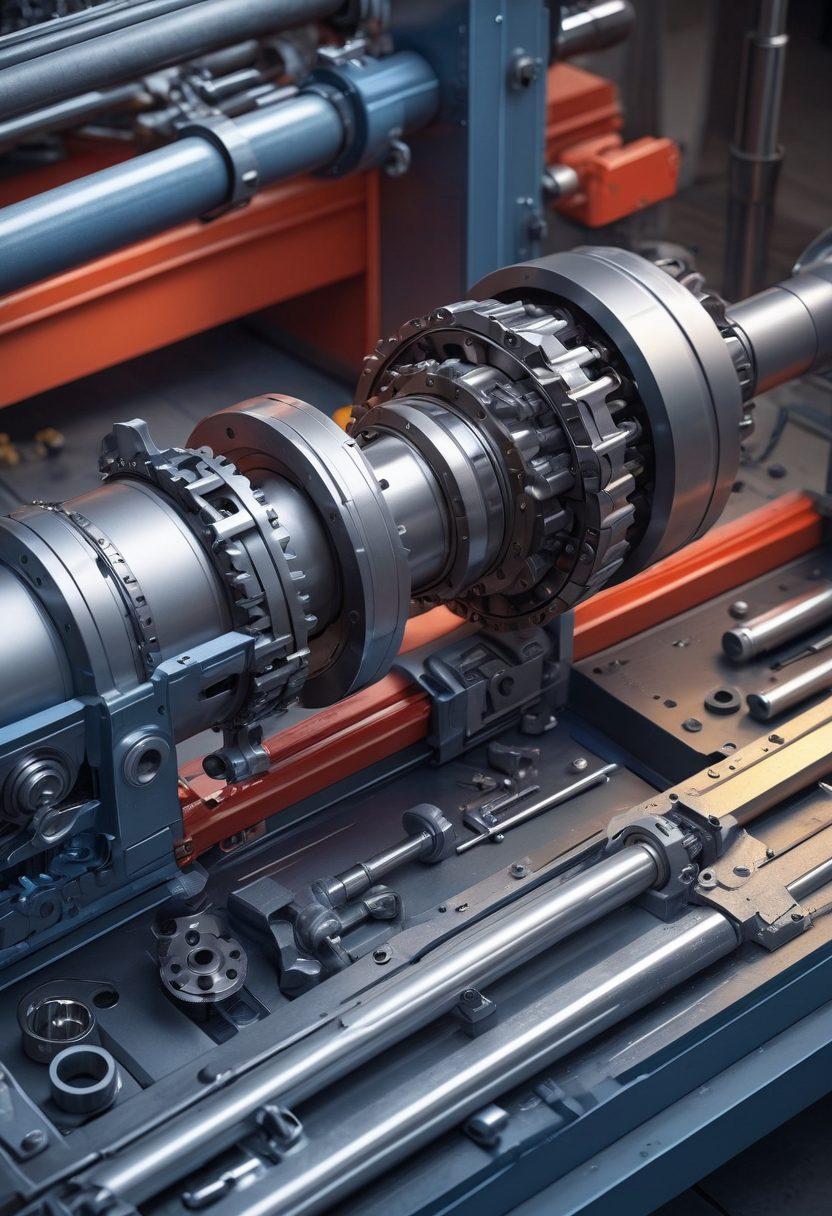

When it comes to the world of power transmission components, the shaft assembly is often the unsung hero. Imagine the intricate dance of a finely-tuned engine or the powerful thrust of a propeller in motion. Without a well-designed shaft system, none of these astounding feats of engineering could occur. So, how do we ensure that our shafting systems deliver optimal performance? In this blog, we will delve into the secrets of shaft assembly, exploring maintenance tactics and design strategies that can help you unlock the full potential of these critical components.

One of the key aspects to consider in shaft design is understanding the roles of different parts such as the crankshaft and the camshaft. The crankshaft, often referred to as the heart of the engine, is pivotal in converting linear motion into rotational motion. Have you ever thought about how essential this transformation is for your vehicle's performance? On the other hand, the camshaft, which controls the timing of the engine's intake and exhaust valves, plays a vital role in how smoothly power is transmitted. By ensuring that both shafts are designed correctly, you can drastically improve your engine's output and longevity.

Maintenance is another critical factor that cannot be overlooked when it comes to shaft assembly. Just like a fine-tuned instrument, a mechanical shaft requires regular attention to function optimally. This includes proper lubrication of bearings, ensuring that every pivot point is well-maintained, and regularly inspecting for wear and tear. 'An ounce of prevention is worth a pound of cure' could not ring truer in this context. How often do you schedule maintenance for your shaft assembly? Establishing a routine can drastically reduce the risk of costly repairs down the line.

Moreover, understanding the interplay between various components, such as the drive shaft, rotor, and axle, is crucial for seamless motion transfer. When these elements work in harmony, they create a smooth flowing operation that can handle high torque demands without excessive wear. Whether you're designing an industrial shaft or focusing on the more complex aspects of automotive transmission, remember that each part plays a vital role in the overall performance. So, what can you do to ensure your system operates like a well-oiled machine?

Lastly, it's important to consider how advancements in technology have revolutionized traditional shaft design. Engineers now have access to sophisticated materials and cutting-edge designs that enhance performance and durability. This opens the door to innovative solutions that might just change the game for your shaft assembly. Are you ready to explore these modern approaches and how they can elevate your power transmission system? The journey doesn't end with design; it's an ongoing balance of creativity and knowledge that can lead to astonishing improvements in performance.